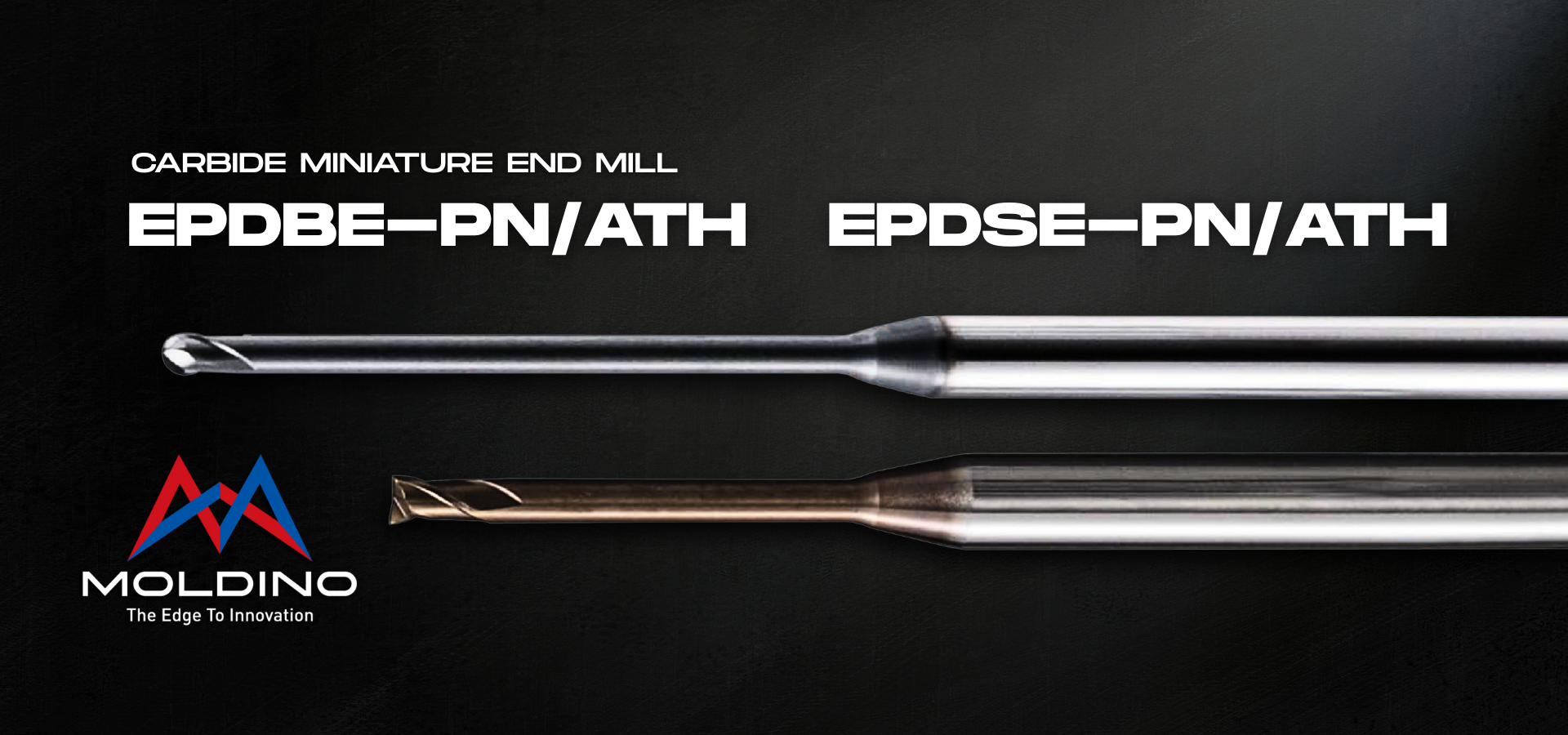

MOLDINO - Carbide Miniature End Mill : EPDBE-PN/ATH EPDSE-PN/ATH | JSR GROUP

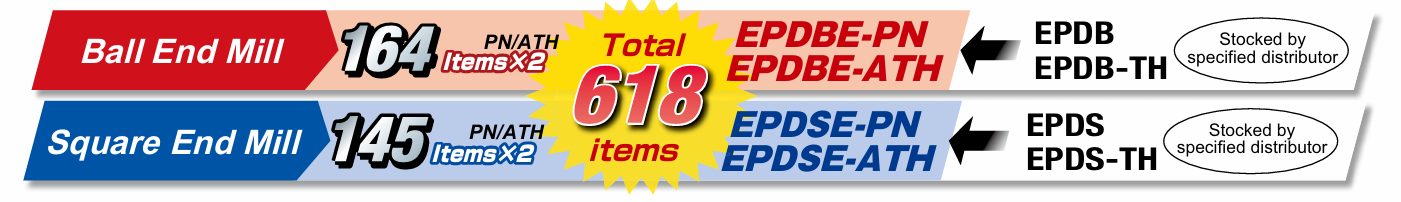

Carbide Miniature End : Mill EPDBE-PN/ATH EPDSE-PN/ATH

| Features | 01 | Features of Epoch Deep Evolution |

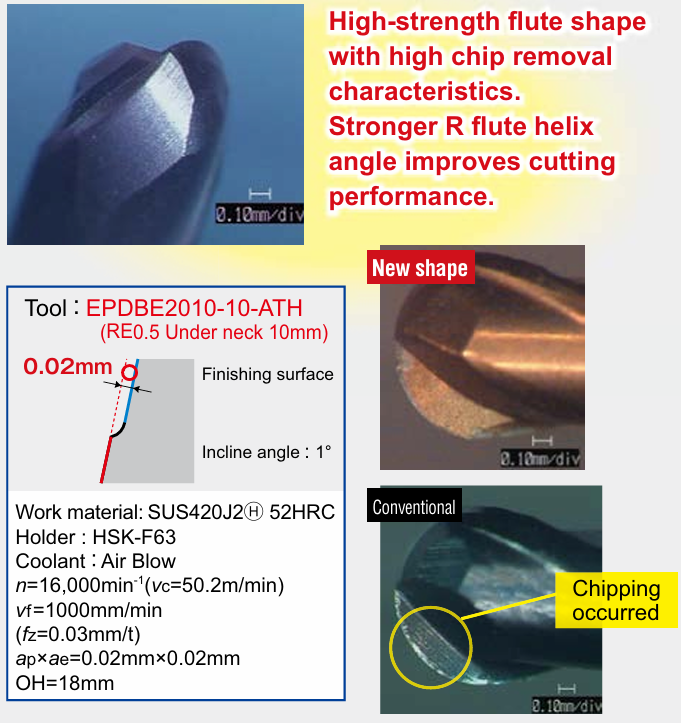

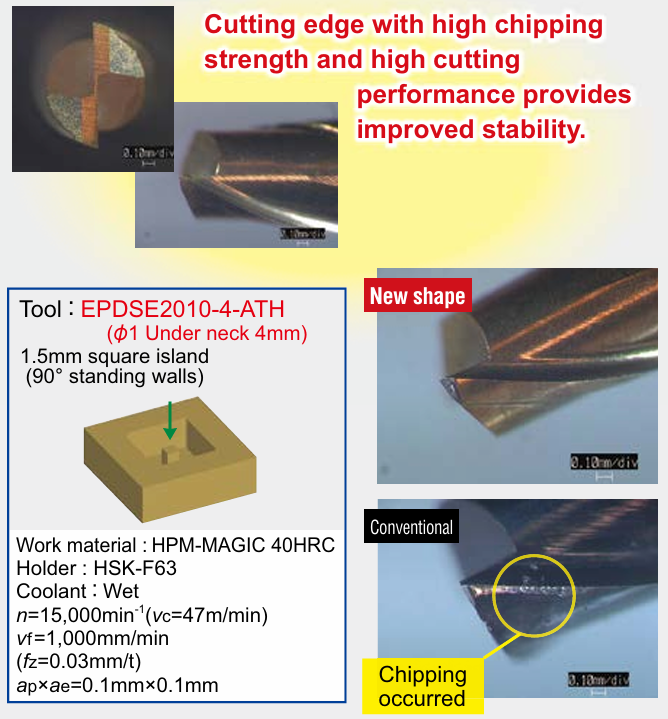

| Flute shape increases resistance to breakage. |

| Epoch Deep Ball Evolution | Epoch Deep Square Evolution | |

|

|

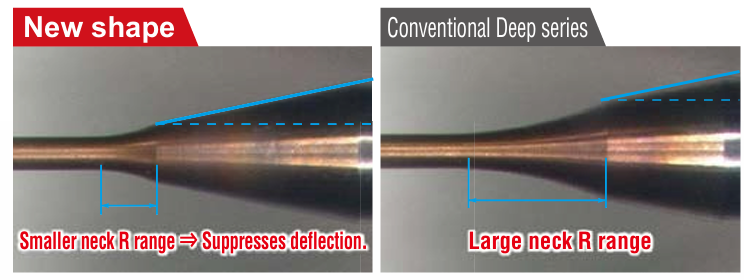

| Improved compound neck shape |

|

Further improves the conventional compound shape of R and taper to both resist breakage and suppress deflection.

Caution |

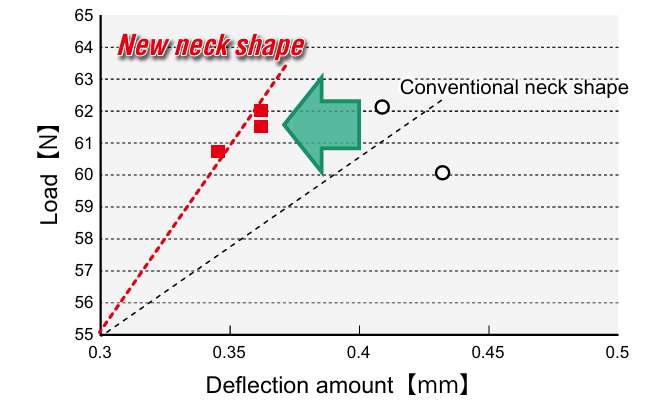

Static load test results Testing tool size φ1×Under neck 6

Deflection suppression effect is high even under the same load. Enables machining with even higher accuracy. |

| Improved compound neck shape |

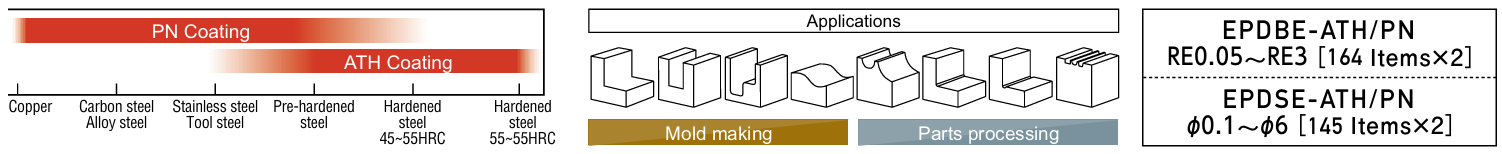

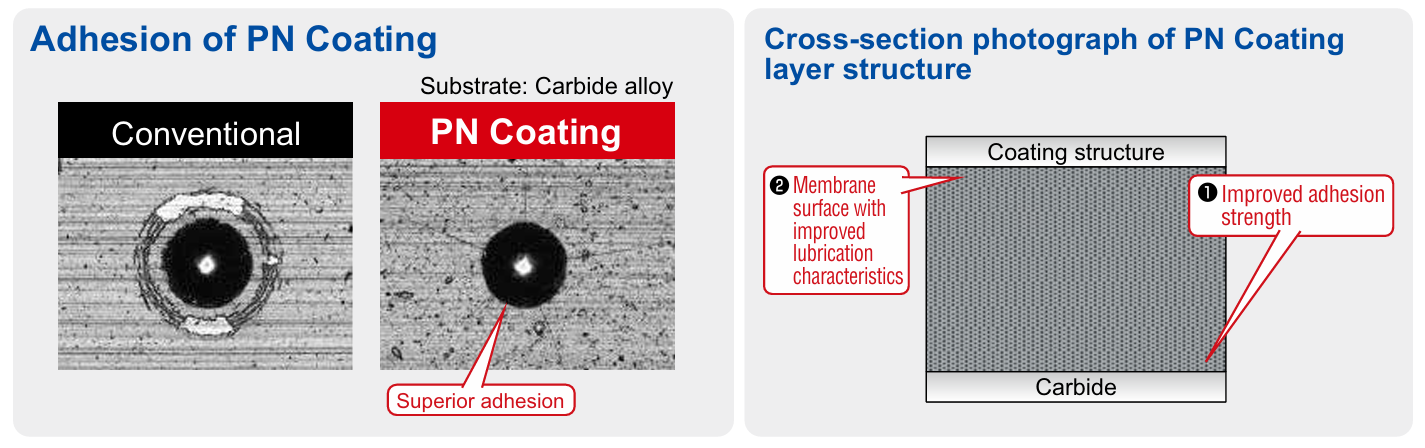

| Features | 02 | New coating with excellent adhesion and wear resistance |

Features

・A heat-resistant coating material with excellent adhesion to the tool substrate was achieved by optimizing the Al content.

・Exhibits with good wear resistance due to Si doping to the AlCr coating layer.

・Exhibits excellent cutting life for cutting materials such as plastic molds, etc. where tool seizure often occurs.

(2x the cutting life compared to conventional products.)

Provides the long life in cutting processing of materials starting with HPM-MAGIC and including prehardened steel, carbon steel, alloy steel, SUS, SKD61, SKD11, etc.

・By improving heat resistance, long life are possible for both wet cutting and dry cutting.

Note) This product obtains less electric conductivity. Therefore, Please caution of using electric transmitted measuring systems.

Characteristics

| Features | 02 | Improved heat-resistant coating |

Features

・Hardness and oxidation resistance of TH Coating is further improved. Enables longer life and higher efficient when cutting high-hardness materials.

(Si nano composite coating with finer crystal particles)

・Exhibits amazing performance when cutting high-hardness materials (55HRC or higher) Cold-worked die steel, HSS, tool steel.

・Long life for both dry cutting and wet cutting